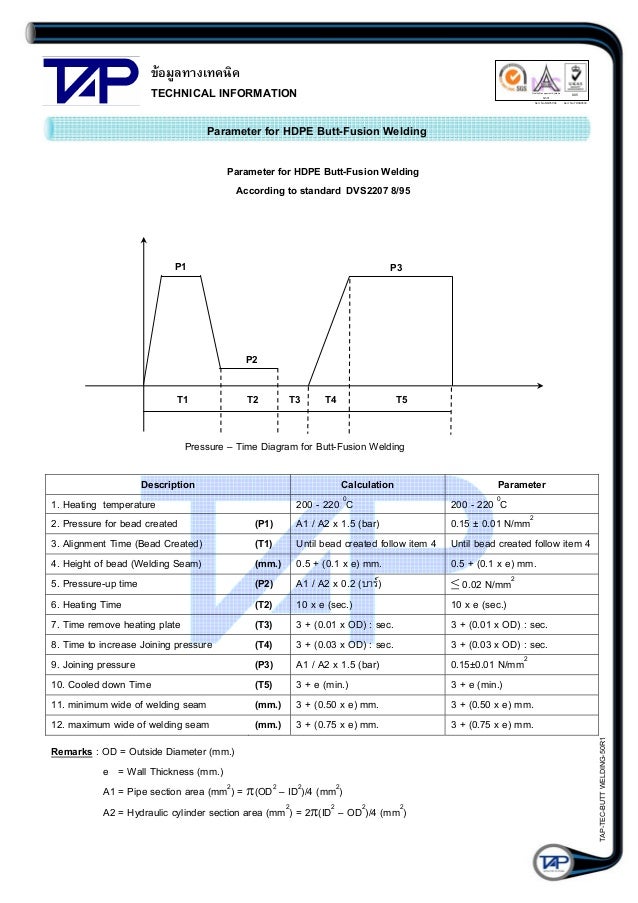

It would not typically be used in a small scale system, like a home or a school or other general building. Polyethylene Joining Procedures Butt Fusion Joining Procedure for Field Joining of Polyethylene Pipe. An integral part of any pipe system is the method used to join the system components. Canadian regulations When used to join Uponor Infra polyethylene gas pipe and fittings, Uponor Infra fusion joining procedures are qualified in accordance with Canadian Standards Association Regulations. Set up the welding machine with all the accessories according to the welding pipe size.

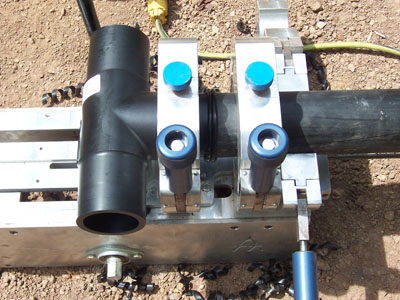

Check if the machine is functioning. All of the problems or missing parts must be fixed prior to the start of the welding operation. There are different types of fusion including saddle fusion or socket fusion, but in this talk we will talk about butt fusion. Like stated above, the actual machines vary greatly in design and use, but the overall process is the same.

EQUIPMENT Mirror Welding Machine 2. Electrofusion Installation Procedure Manual It is important to read and understand all instructions before attempting a fusion. Permanent field installations should be done only by operators who have been properly trained and certified as qualified. Correctly designed equipment with proper maintenance: Correct welding temperatures, welding procedures and pipe facing tools must be maintained in tolerance and in good condition.

The resulting joint, if it has been properly made, is as strong as the original pipe and can withstand all the loads applied during routine installation and operation. Butt fusion welding of plastic pipes is described concisely, including tips for a successful weld , machine set up, aligning and clamping the pipe , preparing the pipe , noting heating and cooling times and fusion pressures, welding , cooling and inspection. Before welding begins, the surface of the polyethylene must be ground down, to expose the virgin HDPE. Welding the Root Pass Before beginning to weld the pipe , the procedure should be checked to assure that the correct electrode is being used. This includes the diameter and the classification of the electrode.

The welding con-sumable should be selected to correctly match (or overmatch) the strength of the pipe. HDPE pipe joint - Duration:. Sample of PE pipe to drain completely trapped air care should be filled in the test environment. The highest point in the test sample when filling ventilation may be necessary to clear the air pockets. WELDING PROCEDURE SPECIFICATION.

Cut pipe and rough bonding surfaces. Fusion Welding : The seam shall be produced by self propelled wedge welding apparatus. The apparatus shall be equipped with gauges to monitor weld temperature. Weld temperature and machine speed shall be varied according to ambient conditions in order to maintain and demonstrate a consistent acceptable weld.

The Butt welding method is the most common welding method currently used for joining hdpe pipes and fittings. The pipe joining method is a process in which the two ends of the pipes to be heated and welded by using a butt welding machine and the both ends are pushed toward each other by pressure under a certain temperature. After the pipe has been joine fill it with water, carefully bleed off any trapped air. The tack weld holds the material in place during grinding and welding operations.

All patches should have rounded corners. Hot Gas Welding (HGW), also known as Hot Air Welding (HAW), is a plastic welding technique using heat. A specially designed heat gun, called a hot air welder, produces a jet of hot air that softens both the parts to be joined and a plastic filler ro all of which must be of the same or a very similar plastic.

From small hand-held fusion equipment to larger electrofusion machines, Ferguson is your source for.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.