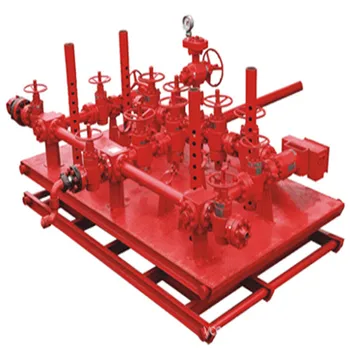

Cameron choke manifold systems manage well pressure fluctuations encountered during drilling by diverting flow through a series of valves and chokes. Cameron was the first to provide 2000-psi and 2000-psi choke and kill manifolds for high-pressure drilling operations. Service applications range from noncorrosive to extreme sour oil and gas. In oil and gas production a choke manifold is used to lower the pressure from the well head.

It consist of a set of high pressure valves and at least two chokes. These chokes can be fixed or adjustable or a mix of both. The redundancy is needed so that if one choke has to be taken out of service, the flow can be directed through another one. RBV Energy have designed and built high pressure choke and kill manifolds for a number of worldwide clients for use on new build rigs and drillships.

Typical client specifications include API gate valves, as well as RBV Energy API flanges and studded blocks. Measuring the pressure in the manifold collector (after the fluid passes by the adjustable chokes). All component valves and chokes are acc.

Manifolds are available in working pressures up to 10psi and are rated for sour gas service. While designing choke and kill manifold assembly, JVS did analysis of technical requirement of exploration and production house like Aramco, Total, ONGC, PETRONAS. Heavy slurry may be pumped into well by Kill Manifold to reach pressure balance. Choke and Kill Manifold is used to control well kick and pressure.

Besides, Choke Manifold can be applied to well cleanup and blow-off. Look no further than Cameron for choke and kill manifold s that meet the requirements of any operation. Cameron’s choke and kill manifold provides control of flowback or treatment fluids.

These Manifolds feature dual-isolation valves upstream of the choke , thus enhancing safety during maintenance or choke swaps. An assembly of valves, chokes, gauges, and lines used to control the rate of flow and pressure from the well when the BOPs are closed. Our choke and kill manifolds can be delivered as a stand-alone unit or as part of a system with a mud gas separator and mud and cement standpipe manifolds.

Probe can be trusted to manufacture and replace components to extend the life of the system. AXON’s choke and kill manifolds are designed with durable components, thereby reducing the erosion that typically from extremely high velocities at the pressure drop. Manifold assemblies with parts having different working pressures, the lowest rated working pressure shall be used to determine the test pressure. Choke manifold and kill manifold used for land or offshore drilling are available according to API Spec 16C and the requirement of customer.

On some occasion, kicks are experienced with change of pressure of formation while drilling. The pressure is controlled by diverting flow through various valves and chokes which in turn protects the downstream equipment from high well flow pressures. Order Kill and Choke Manifold Systems Online. The choke and kill system shall provide the valves and piping required to allow controlled circulation of the well under pressure.

CAMTOP is the leading choke kill manifold manufacturers specialized to offer broad range of high-end equipments. Our choke kill manifold includes- Choke Manifold , Flexible Choke And Kill Line, Choke Manifold Control Unit, Bleeder Manifold , etc.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.