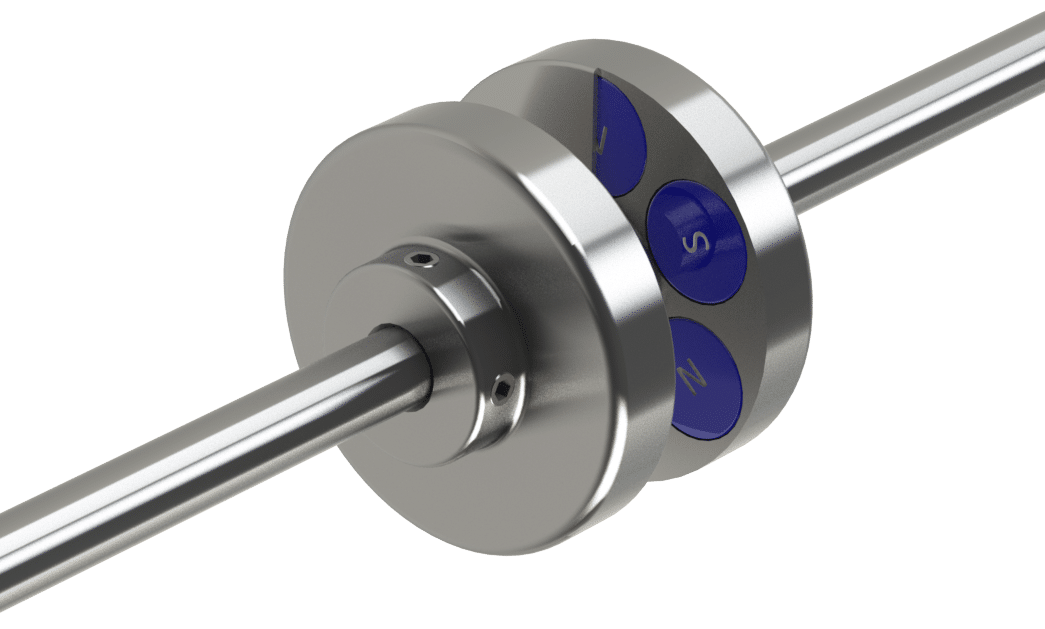

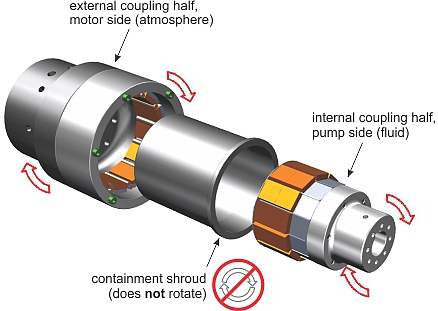

Proudly Made in the USA. A magnetic coupling is a coupling that transfers torque from one shaft to another, but using a magnetic field rather than a physical mechanical connection. Magnetic shaft couplings are most often used for liquid pumps and propeller systems, since a static, physical barrier can be placed between the two shafts to separate the fluid from the motor operating in air.

Can a magnetic coupling pump run dry without damage? Magnetic coupling is a new kind of coupling ,which connects motor and machine by permanent magnetic force. They work in the sealless magnetic drive pumps,which transporting volatile,flammable,explosive and toxic solutions with no leakage.

Coaxial magnetic couplings are configured so that one member. Face to face magnetic couplings are configured. Torque Couplings – Face to Face. Linear Couplings – Tubular. Tubular magnetic couplings are configured so that one member.

They are used transfers force between different magnetic fields, which has no physical connection. The advantage of a magnetic coupling is it’s capability to transfer power without any direct touch. Can be used to couple across a thin barrier, making a perfectly hermetically sealed rotary feed-through. Serves as a wear-free slip clutch - under overloa the magnetic coupling simply slips to the next position. In the MXC OEP magnetic couplings , this slip is exactly degrees.

It ensures a hermetic separation of the drive and the driven side in its main function as sealing element in pumps and agitators. Principles of operation. The coupling upgrade project was initiated as a result of a failure event on the No.

Fill Your Cart With Color today! Features: Magnetic torque transmission, clean and efficient. Big transmission torque, with small size. Standard magnetic coupling. Our standard coupling , on the shelf.

Q: Failure of magnetic coupling ? The magnetic coupling fails when the permanent magnets are demagnetized or loss magnetism. The main methods of magnets failure are high temperature, vibration, reverse magnetize etc. Dangerous or precious media remain isolated in the closed system circuit. DST magnetic couplings can be used in various areas: besides the chemical, pharmaceutical and food industry, DST products are applied in biotechnology, in industrial furnaces, in water management, in compressors, in measurement and dosing technology, in hydraulics or in petrochemistry. That is why these are also described as “seal-less pumps”.

The couplings are synchronous and the output shaft speed is exactly equal to the input speed and these types of coupling can be designed with a maximum 1 efficiency. In its most general form, the magnetoelectric effect (ME) denotes any coupling between the magnetic and the electric properties of a material. Magnet Sheets and Rolls with adhesive or vinyl. What Is Magnetic Coupling ?

No comments:

Post a Comment

Note: only a member of this blog may post a comment.