What are the performance measures for pipeline leak detection? Why do you need a gas leak detection system? Where is my leak detection pump located?

What type of leaks can a leak detector be used to find? For maximum efficiency it’s important that pipeline operators have a leak detection system (LDS) that they can rely on and ensure that they can detect leaks quickly, locate leaks accurately, issue minimal false alarms, be easy to retrofit, work effectively under all operating conditions and use sensors with high reliability and low maintenance. Older oil pipeline leak detection systems were based on flow balancing, measuring at each inlet and outlet: basic statistics helped determine the probability of a leak. This approach is adequate under very stable pipeline flows.

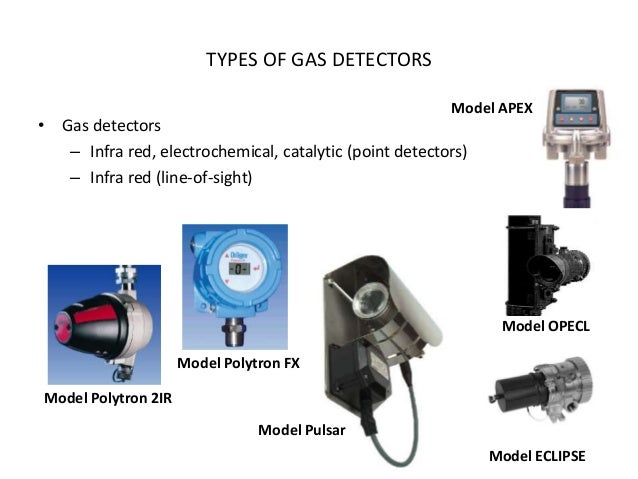

Detecting leaks in your pipeline network is critical, but ineffective pipeline integrity programs can result in a lack of actionable data, failure to detect small leaks and false alarms that take operators away from real situations that can lead to critical events. Internal leak detection systems are one of the most common technologies used to detect a leak. These systems use point sensors to track flow rates, as well as apply mathematical and statistical computations to monitor flow rates, pressures, temperatures and product characteristics.

Although these systems are useful in identifying leaks , they lack in sensitivity. Leaks take longer to detect , and small leaks may go completely undetected. Sensors placed at regular and strategic intervals along all pipelines measure everything from the wave patterns of the product in the line, to temperature, flow and pressure – and all this information is then share via SCADA, with control room operators. Available as stand-alone or integrated with video, UAVs, satellites etc. In such cases, leak detection systems can help minimize damage to people, the environment, and the company image as well as the high costs for repair, renovation, indemnity, breakdowns and the lost value of the liquid or gas that has been released.

In addition, there are also different official regulations related to pipeline leak detection. Smart monitoring and protection of pipelines. Comprehensive suite of modules for leak , theft and line break detection , plus monitoring of tightness and lifetime stress. Complete and sensitive protection of oil, gas, water and multiproduct pipelines. From single software applications to full packages including instrumentation.

The DTS monitoring system can be used along long distance oil and gas pipelines with additional stations situated every 60km along the pipeline , providing full coverage of the entire pipeline. Leak Detection System for Oil and Gas Pipelines. We offer the complete DTS monitoring solution package, including the initial application design input,. The primary purpose of leak detection systems (LDS) is to help pipeline controllers to detect and localize leaks. LDS provide alarms and display other related data to the pipeline controllers to assist decision-making.

Pipeline leak detection systems can also enhance productivity and system reliability thanks to reduced downtime and inspection time. Focusing leak detection programs on large-diameter pipelines is the most effective method in reducing water loss. While there are many methods of locating leaks on water transmission mains, inline leak detection is the most accurate because it brings the leak detection sensor directly to the source of the leak. Our system can also be used proactively during hydrostatic leak testing to ensure your infrastructure is working properly and can quickly pinpoint the source of a problem should it arise.

The DTSX leak detection application captures changes in the surface temperature of the pipeline in 1-meter units at least every seconds. That means it can immediately detect leaks of any size, and even makes it easy to find the location of a leak. With reservoir, well and pipeline integrity monitoring and leak detection , reliability is paramount. As important as detecting a leak is, the controller’s response is equally critical. An overview of pipeline leak detection and location systems.

Leaking of methane and hydrocarbon gas causes negative impacts on the eco system such as global warming and air pollution. Sahara leak detection is tracked above ground using sensors, which also allows for the precise marking of leaks. This information can be used by utilities to greatly improve excavation accuracy when excavating the pipeline for repairs and maintenance, especially in complex urban environments.

No comments:

Post a Comment

Note: only a member of this blog may post a comment.